Weld Defects

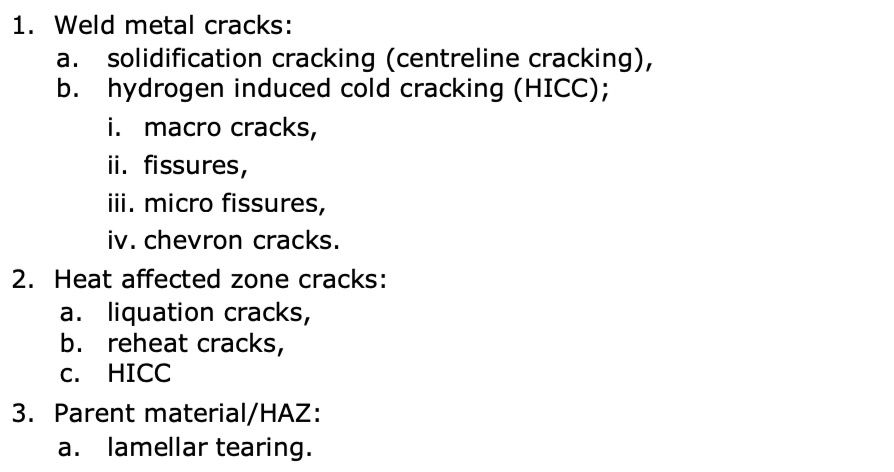

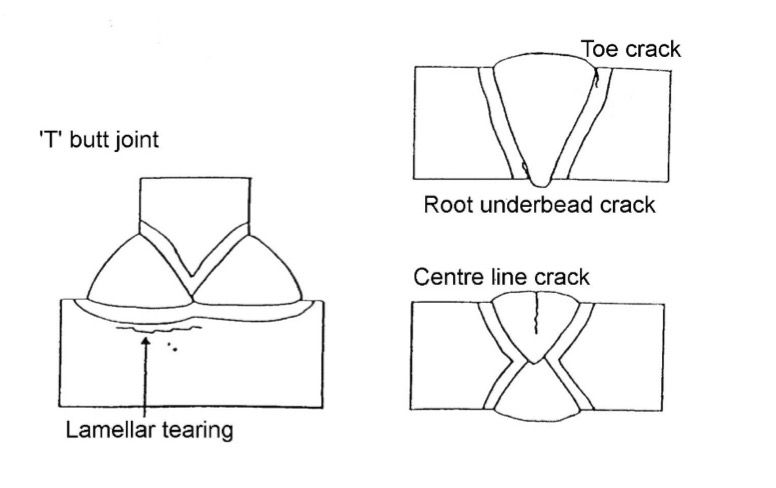

Cracks

Definition: A linear discontinuity produced by fracture. Cracks may be longitudinal, transverse, edge, crater, centreline, fusion zone, underbead, weld metal, or parent metal.

Reference material: Terminology to BS 499-1:2009 Welding terms and symbols: Glossary for welding, brazing and thermal cutting.

There are many types of cracks, some of which only occur with certain types of material. Listed below are some crack types encountered.

Because of the various crack types and causes, a welding inspector, under most circumstances, need only talk in terms of the position of a crack, e.g. longitudinal centre line crack; longitudinal crack in the HAZ of the root (root underbead crack); transverse crack; crater crack etc.

A crack is the most serious type of defect. If a crack exists in the weld zone, the application specification may require the entire weld to be removed (cut out) and rewelded, rather than carry out a localised weld repair. Some application specifications will permit a localised weld repair on the cracked area, but very few specifications will allow the acceptance of a detected crack, no matter how small.

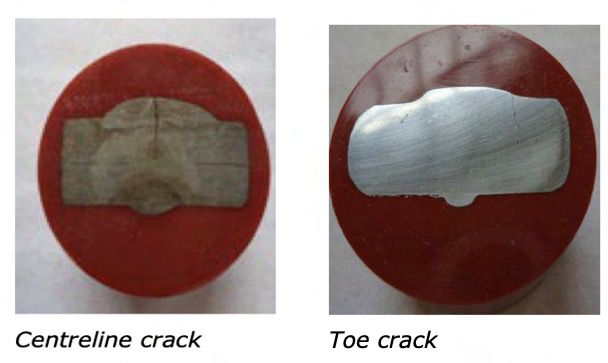

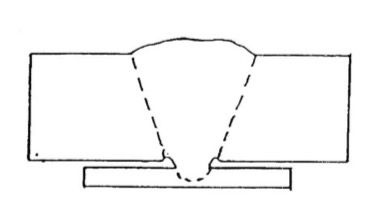

Incomplete root penetration

Definition: The failure of metal to extend into the root of a joint.

Other terms for the same defect are: lack of penetration and lack of root penetration. In the case of double sided welds the terms: lack of inter-penetration and lack of cross-penetration may also be encountered.

Causes:

a. root faces too large,

b. root gap too small,

c. arc too long,

d. wrong polarity, Lack of inter-penetration

e. electrode too large for joint preparation,

f. incorrect electrode angle,

g. travel speed too high for current.

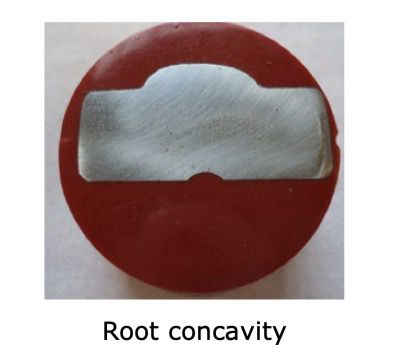

Root concavity

Definition: A shallow groove that may occur in the root of a butt weld.

The terms suckback, concave root or underwashing may also be encountered.

Causes:

a. root face too large,

b. insufficient arc energy,

c. excessive back purge pressure with TIG welding,

d. excessive root grinding (before application of second run)

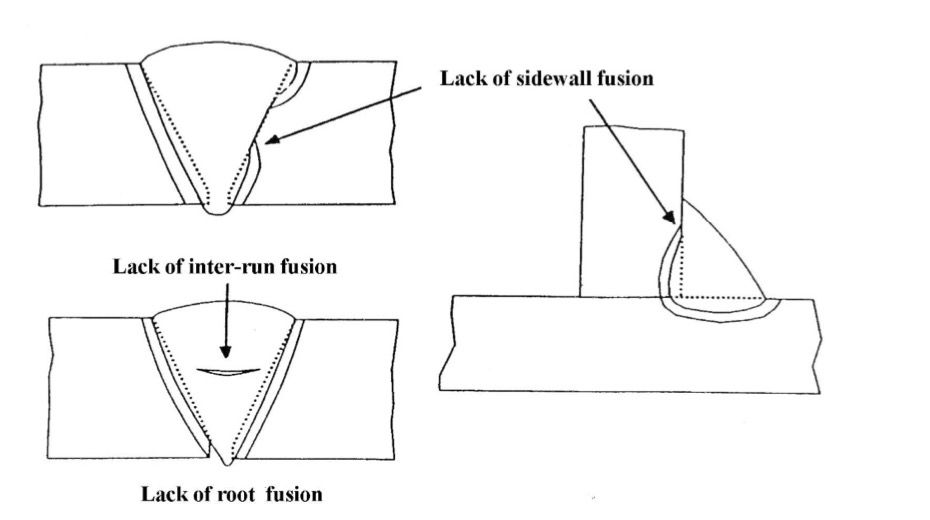

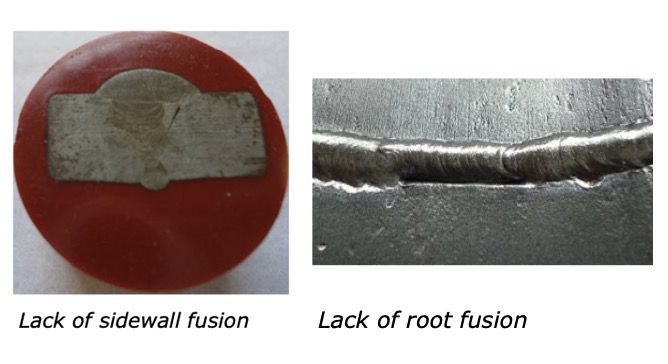

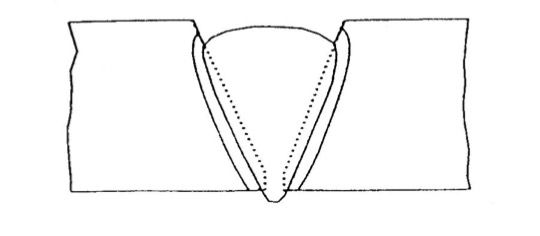

Lack of fusion

Definition: Lack of union in a weld:

- between weld metal and parent metal,

- between parent metal and parent metal,

- between weld metal and weld metal.

Lack of fusion can be sub-divided as shown below:

Causes:

a. contaminated weld preparation - prevents the melting of material beneath,

b. amperage too low,

c. amperage too high - may cause welder to increase his travel speed resulting in a lack of melting on the underlying metal,

d. excessive inductance in MIG or MAG dip transfer welding.

e. De-oxidiser residues in MAG welding.

See also causes for incomplete root penetration.

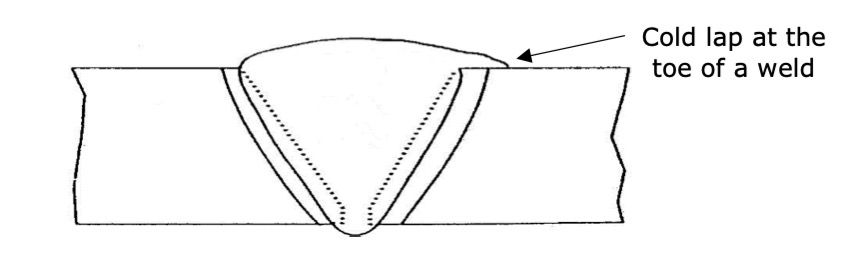

Cold laps

Definition: Cold laps are imperfections, typically at the toe of a weld, caused by metal flowing on to the surface of the parent metal without fusing with the parent material. Cold laps can also be known as overlap.

(This cannot be termed as lack of fusion, as it is not happening on a fusion face)

Causes:

a. Improper welding technique

b. Excessive weld material deposited

c. Contaminated weld preparation; scale, oxides etc.

d. Travel speed too low in MMA welding

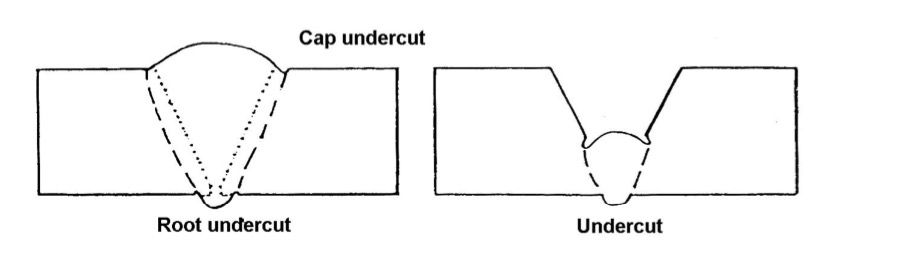

Undercut

Definition: An irregular groove at the toe of a run in the parent material, or in previously deposited weld metal, due to welding.

Causes:

a. excessive welding current,

b. welding speed too high,

c. incorrect electrode angle,

d. excessive weaving,

e. electrode too large.

Incompletely filled groove

Definition: A continuous or intermittent channel in the surface of a weld, running along its length, due to insufficient weld metal. The channel may be along the centre or along one or both edges of the weld.

Causes:

a. de-oxidiser residues in MAG welding,

b. insufficient weld metal deposited,

c. improper welding technique.

Shrinkage groove

Definition: A shallow groove caused by contraction in the metal along each side of a penetration bead.

Causes:

a. Insufficient weld metal deposited,

b. Improper welding technique.

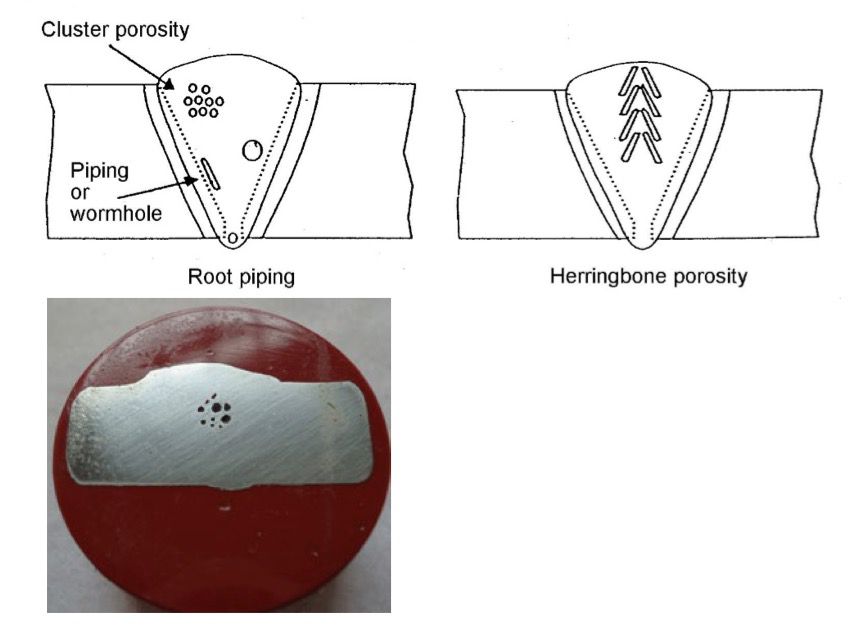

Gas pores/porosity

Definition: A gas pore is a cavity, generally under 1.5 mm in diameter, formed by entrapped gas during the solidification of molten metal.

Definition: Porosity is a group of gas pores. Porosity can be located in the weld body or can be surface breaking.

Other terms which relate to entrapped gas in welds are:

- Blowhole - a cavity generally over 1.5 mm.

- Wormhole (piping) - an elongated or tubular cavity.

- Hollow bead* - elongated porosity in the root bead (pipeline terminology).

- Herringbone porosity - wormholes side by side taking on a herringbone pattern

*Hollow bead is terminology used on pipelines where it is commonly encountered on MMA vertical down (stovepipe) root beads using cellulose electrodes.

Causes (all types):

c. excessive moisture in the flux,

d. excessive moisture on the preparation,

e. contaminated weld preparation: scale, oxides etc.,

f. use of low welding current,

g. arc length too long (especially with basic hydrogen controlled electrodes),

h. damaged electrode flux,

i. incorrect weaving technique,

j. removal of gas shield, e.g. wind on site.

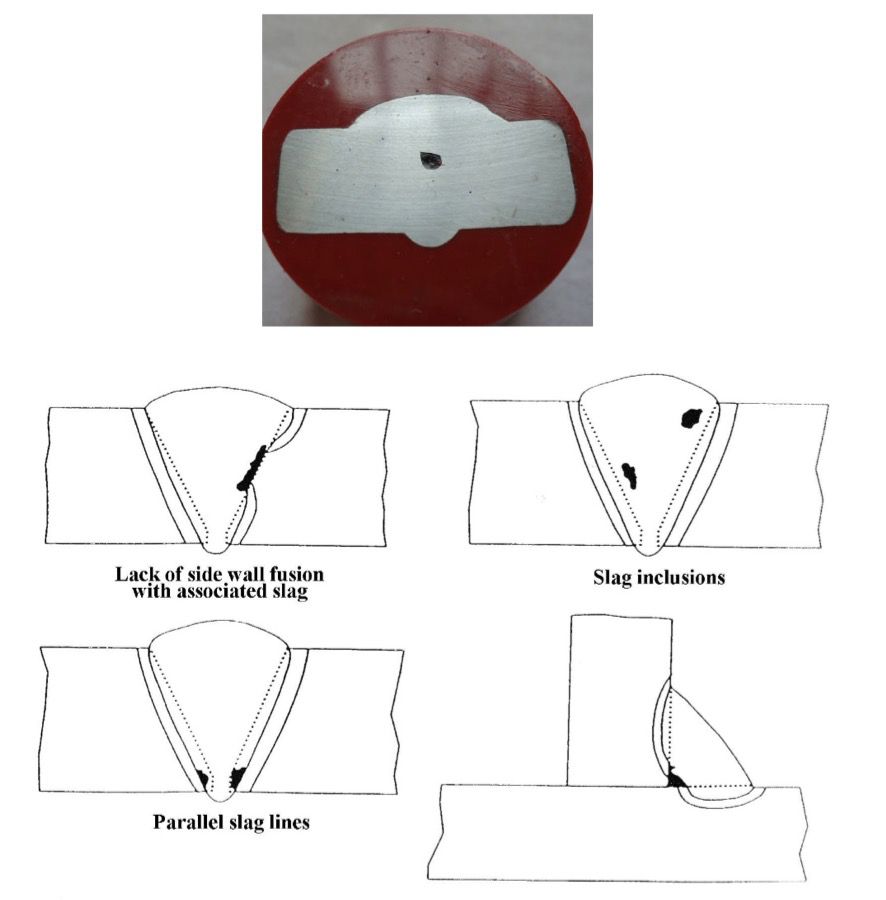

Slag inclusion

Definition: A fused, non-metallic residue produced from some welding processes.

A slag inclusion is an entrapped non-metallic deposit in the weld originating from the welding flux. Linear slag inclusions, or slag lines, almost exclusively exist at the toes of a weld pass. Equiaxed slag inclusions may exist anywhere in the weld.

Causes:

a. insufficient cleaning between passes,

b. contaminated weld preparation,

c. welding over an irregular profile,

d. incorrect welding speed,

e. arc too long.

Tungsten inclusion

Definition: An inclusion of tungsten from the electrode in tungsten inert-gas welding.

Copper inclusion

Definition: An inclusion of copper due to the accidental melting of the contact tube or nozzle in self-adjusting and controlled-arc welding, or to pick-up by contact between the copper nozzle and the molten pool in MIG/MAG.

Burn through

Definition: A localised collapse of the molten pool due to excessive penetration, resulting in a hole in the weld run.

Burn throughs are usually associated with the roots of butt welds.

Causes:

a. excessive amperage during the welding of the root or hot pass on butt welds,

b. excessive root grinding, which may cause the second pass to burn through,

c. improper welding technique.

Crater pipe

Definition: A depression due to shrinkage at the end of a weld run, where the source of heat was removed.

Crater pipes must not be confused with burn throughs or gas pores.

Causes

a. deoxidation reactions and liquid to solid volume change.

b. Too fast cooling rate.

A similar defect that may occur at the end of a weld run is a crater crack (see Solidification Cracking Unit PRT8).

Methods employed to avoid these defects at the end pf the weld run can be run on/run off tab or by using oversized plates.

Arc strike (stray flash)

Definition*: Damage on the parent material resulting from the accidental striking of an arc away from the weld.

Arc strikes may have a very brittle structure, especially on steels with a high carbon equivalent.

Causes:

a. electrode straying onto parent material,

b. electrode holder with poor insulation touching the workpiece,

c. poor contact of the earth clamp.

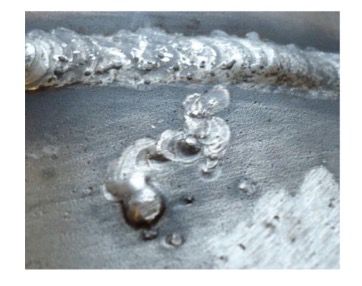

Spatter

Definition: Small droplets of electrode material which have strayed away from the arc, which may or may not have fused to the parent plate.

Causes:

a. excessive arc energy,

b. excessive arc length,

c. damp electrodes,

d. arc-blow.